eviXscan 3D Suite 2.7 – the latest version of the 3D software from Evatronix

27 stycznia 2021

eviXscan 3D scanners and 3DWORX support innovative automotive projects

5 lutego 2021

3DWORX – use of eviXscan 3D Heavy Duty Optima scanner in the Blackstone Tek Hypertek Electronic Motorcycle development project

3DWORX (www.3dworx.co.za) is the sub-Saharan distributor for eviXscan 3D scanners manufactured by Evatronix in Poland. A company from South Africa offers services in the field of high-precision 3D scanning, CAD design, reverse engineering, and 3D printing.

What is Blackstone Tek (BST)?

Blackstone Tek (BST) is an innovative company that builds carbon fiber performance products. It is a combination of the business profile and a love for racing which enables them to create exceedingly strong but still lightweight wheels, and fuel tanks, swingarms, fairings and custom-built components for iconic motorcycle and automotive brands.

Challenge

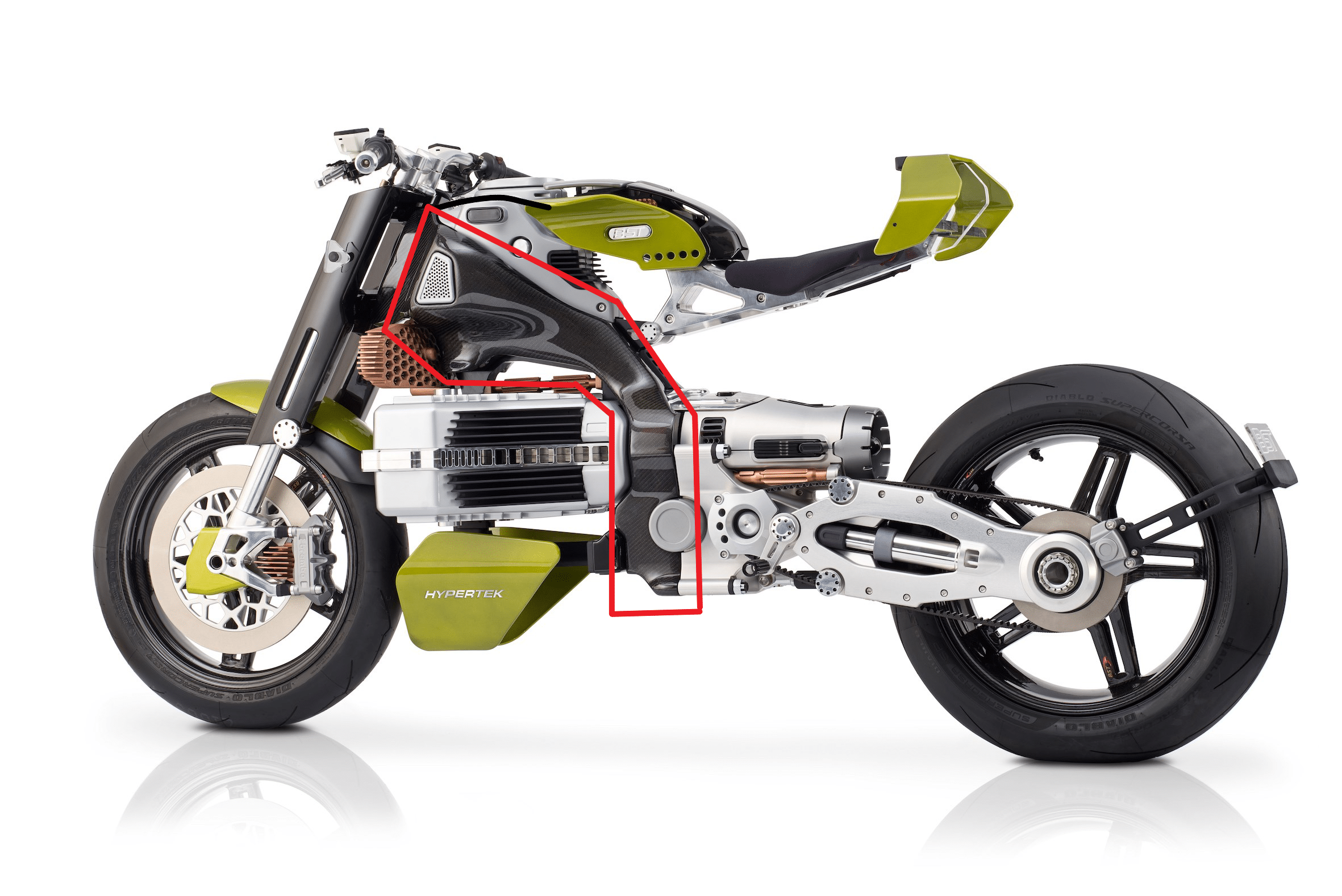

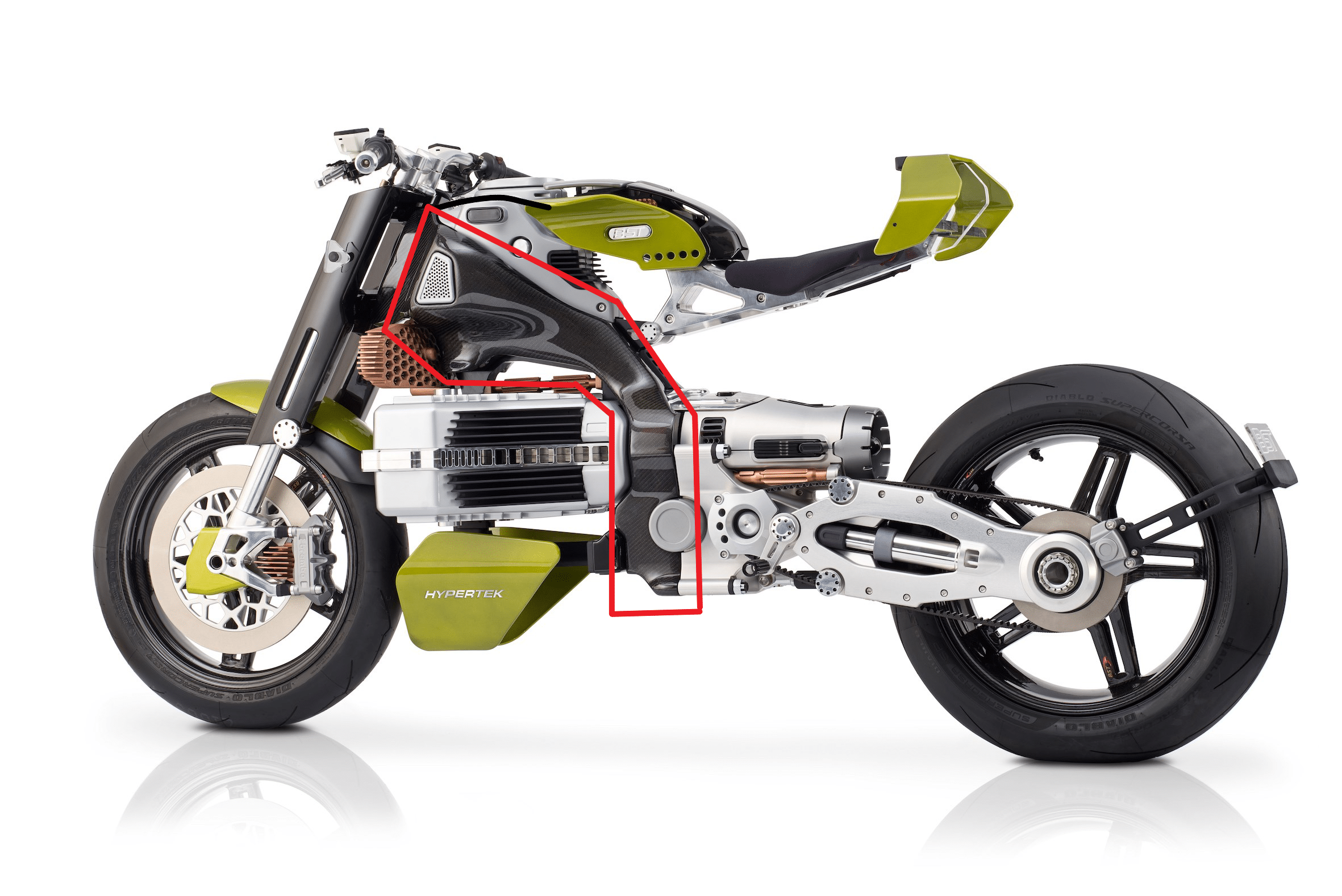

Design the most innovative electric motorcycle using CAD, but also hand-sculpting some prototype parts is the essence of the work to achieve an original organic aesthetic. The Master designer is Pierre Terblanche, responsible for the following styling motorcycles: Ducati 999, the HyperMotard and the SuperMono.

One of the challenges in this project was to digitize the compound curved components that were hand sculped into CAD models so that moulds can be manufactured for production lay-up of the carbon fiber parts.

Solution

The solution used by 3DWORX is to combine CAD modeling with 3D scanning. The entire motorcycle design can be represented in CAD thanks to the application of eviXscan 3D Heavy Duty Optima scanner, the eviXscan Suite 3D scanning software and the 3D Systems Geomagic Design X software for reverse engineering.

Results

The overall result was an efficient successful reverse engineering process for prototype parts with compound curve shapes. In addition, developed CAD files can be used for CNC machining of molds for carbon fiber part manufacturing.

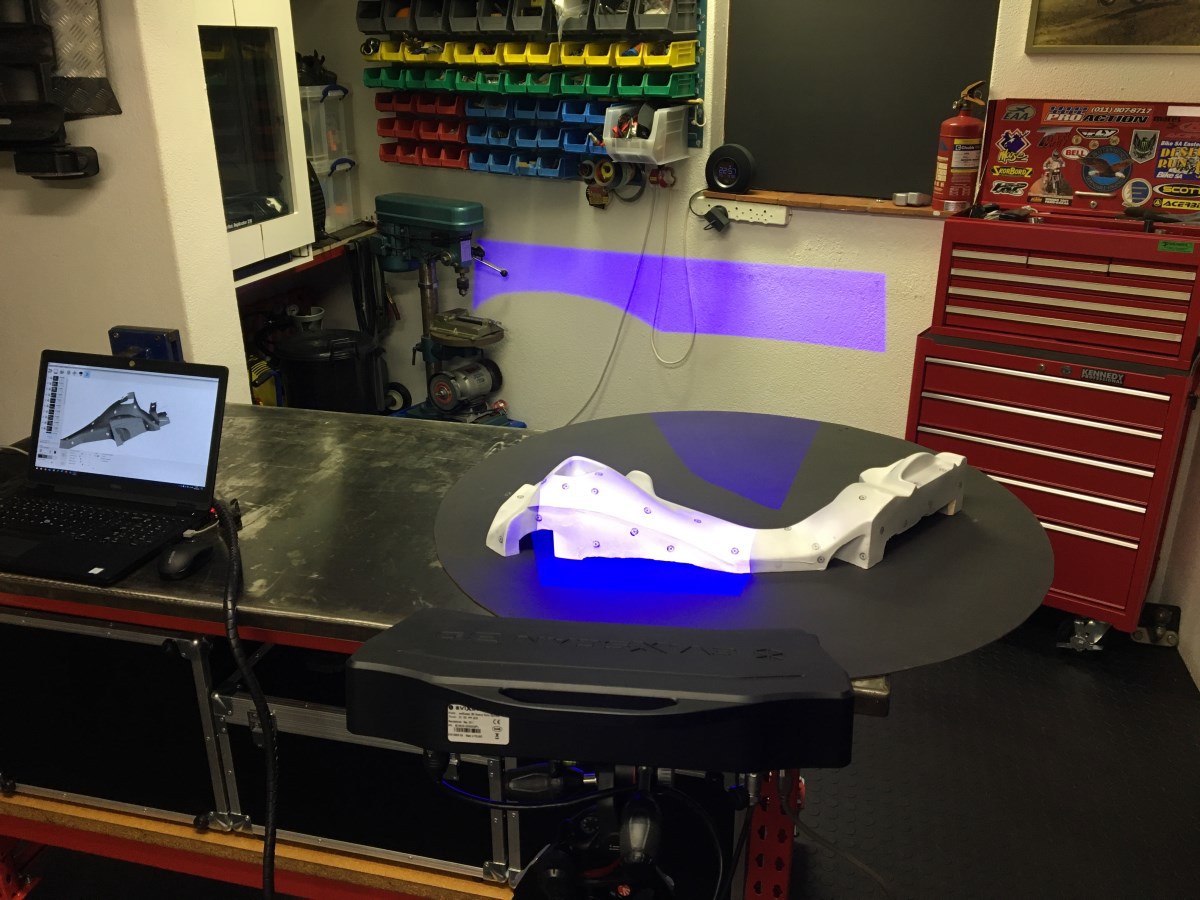

Using of eviXscan 3D Heavy Duty Optima scanner

The primary tool of the process conducted by 3DWORX was eviXscan 3D Heavy Duty Optima scanner – a professional high-precision 3D scanning device for reverse engineering, contactless quality control and fast prototyping of medium-sized models.

Essential technical characteristics of the scanner:

high accuracy measurement (up to 0.0183 mm),high point density (95 pt/mm²),

large scanning volume (250 mm x 170 mm x 120 mm),

5 Mpix cameras,

blue LED light source,

certified precision to VDI/VDE 263 Part 2, 4.1 Ps standard,

robust mobile construction.

Step 1

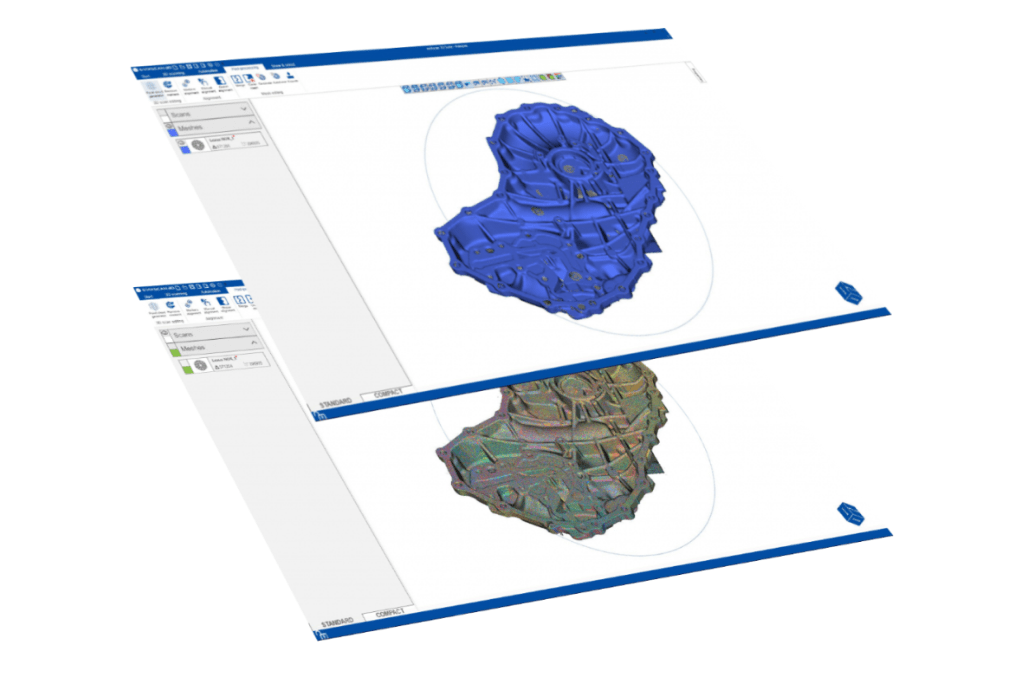

In the first step one of the two side patterns were scanned with the eviXscan 3D Heavy Duty Optima structured blue-light. The objective was to achieve the highest possible accuracy. Each pattern was sprayed with an extremely thin white contrast and had eviXscan unique markers attached for quick yet very accurate pre-alignment in the eviXscan 3D Suite software of multiple scans sets from various orientations.

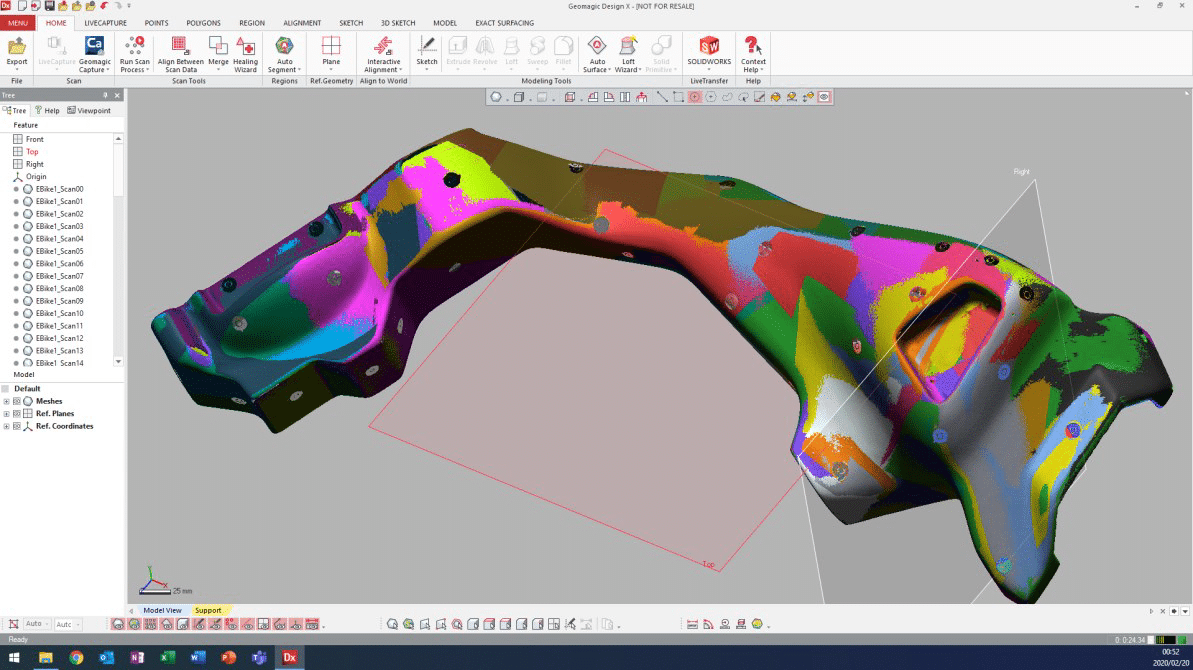

Step 2

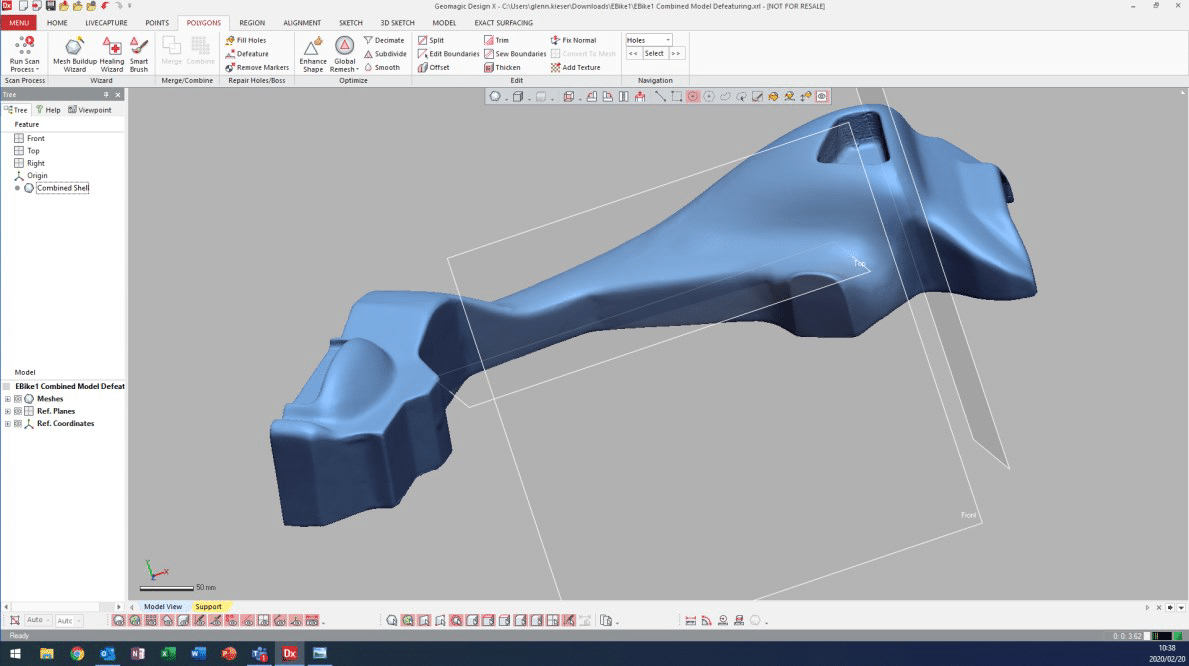

In the next part of the process 3DWORX used Geomagic Design X software for reverse engineering to create a high-fidelity surface mesh, remove markers, fill-in holes and edit the scan.

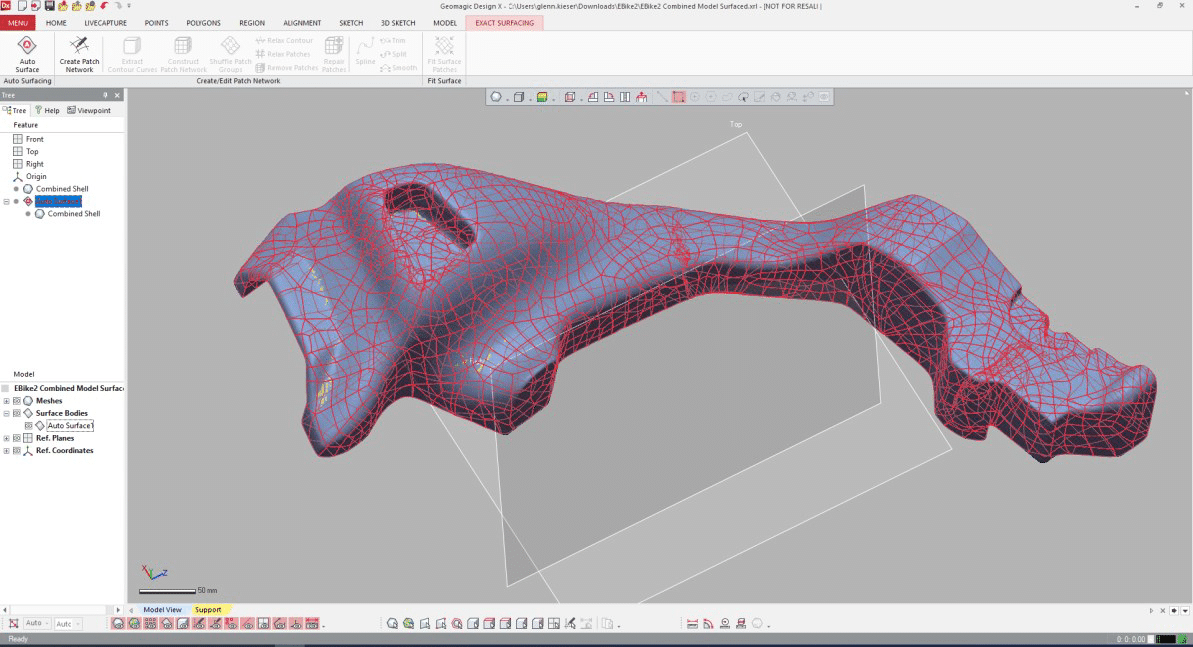

Step 3

Moreover, Geomagic Design X was used to extract geometric surface features and automatically generate form following surfaces over the organic-shaped sections.

Step 4

The software exports 3D parametric models including the geometries, topologies, modeling histories, and parameters directly to popular feature-based CAD systems including Autodesk®, AutoCAD®, Autodesk® Inventor®, Autodesk® Fusion 360®, CATIA®, PTC® Creo®, Siemens® NX™, Siemens Solid Edge®, and SOLIDWORKS®.