3D scanning in art

17 marca 2019

Automotive: Shapers Advanced Design Studio

2 lutego 2020

Cooper Standard Automotive is one of the leading suppliers of plastic and rubber components for the automotive industry. This global leader specializes in the production of car body seals, braking systems, fuel hoses, and air-conditioning systems for a wide portfolio of automotive brands.

making new forms and tools is not only faster, but above all cheaper

Reverse engineering

Cooper Standard based in Bielsko-Biała (Poland) introduced an eviXscan 3D solution into their maintenance section. The use of 3D scanning enabled restoration of technical documentation of molds used in production. Now, preparation of new forms and tools is not only faster, but above all, much less expensive by producing them in their factory tooling department or outsourcing their production to external suppliers. As a result of implementing an eviXscan 3D solution, Cooper Standard has shortened production time of such elements and lowered costs generating savings.

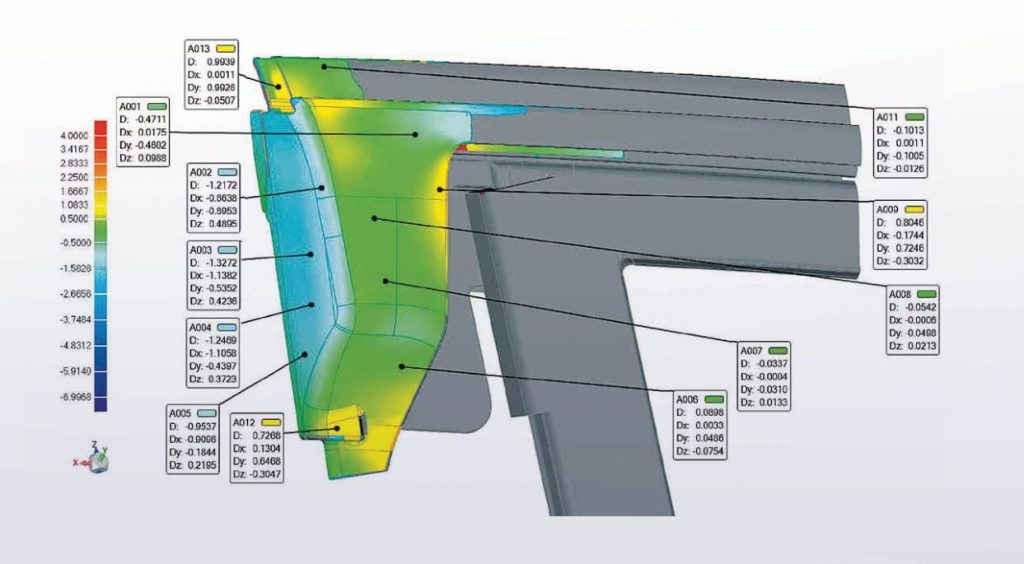

Quality control

The use of 3D scanning in the quality control department ensures the highest quality of no finished products by comparing them to the CAD models supplied by the customer. Our customer thanks to the use of 3D scanning has the full confidence that their products meet the highest standards of the automotive industry, and that the product quality is in line with the expectations of their customer. Implementation of an eviXscan 3D solution enabled precise quality control of no finished rubber products, and shortened the measuring time.

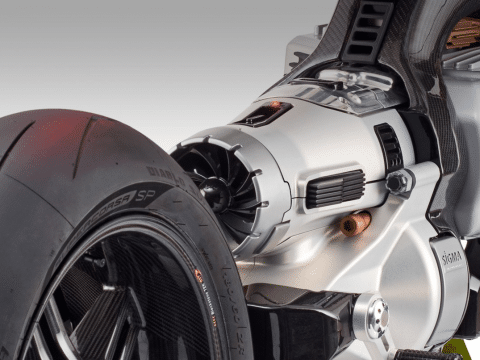

Rapid prototyping

The use of the 3D scanning in the R&D department has enabled rapid and less expensive improvement of the molds and tools used in production. Modifying prototypes has been done four times faster which accelerates the ramp up of commercial production of ordered components thereby generating annual savings.