eviXscan 3D scanners are designed to meet the growing demands and requirements of the market for reliable, fast and accurate metrology devices used in reverse engineering, contactless quality control, 3D modeling and rapid prototyping.

We provide complementary services related to 3D scanning:

- 3D scanning

- 3D modeling

- reverse engineering

- non-contact quality control

Quality control

We offer solutions for non-contact quality control: automated and robotic systems, as well as systems designed for specific customer requirements

Properly selected accessories allow you to scan details with complex shapes or shiny surfaces. Stable stands and rotary tables make the scanning process even more effective.

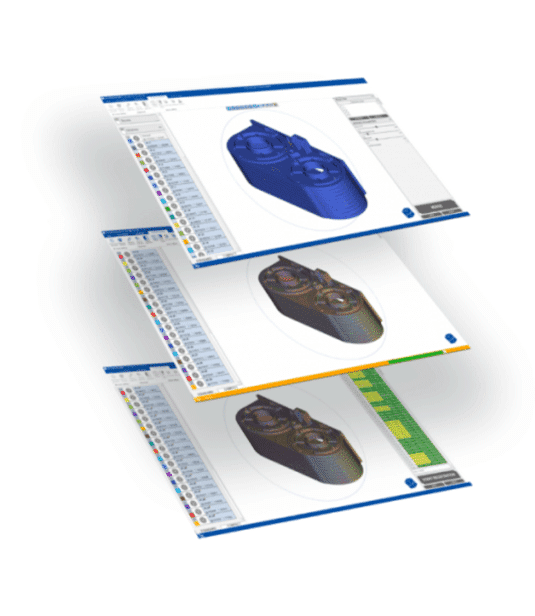

The software together with professional 3D scanners is a complete solution for reverse engineering, quality control and rapid prototyping.

See how we can change your business with innovative 3D technology. Our experts will:

- scan, create a CAD model or carry out quality control of the indicated detail object

- demonstrate application of our 3D scanners on the example objects provided by you

- answer your questions and train your staff

- analyze your needs and prepare the right offer

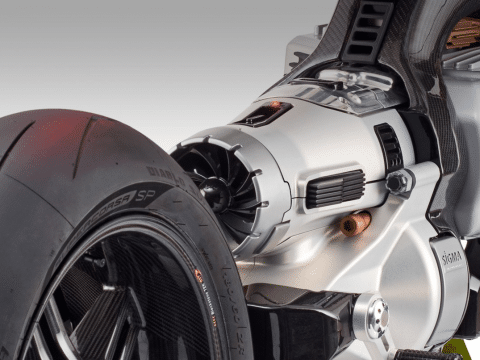

Industries we work with

The 3D scanning technology offered by our company supports the activities of many enterprises. Thanks to a diverse portfolio of offered products, eviXscan 3D scanners can be used for quality control tasks, reverse engineering, and rapid prototyping. We have experience working with a wide range of industries:

Case studies

News

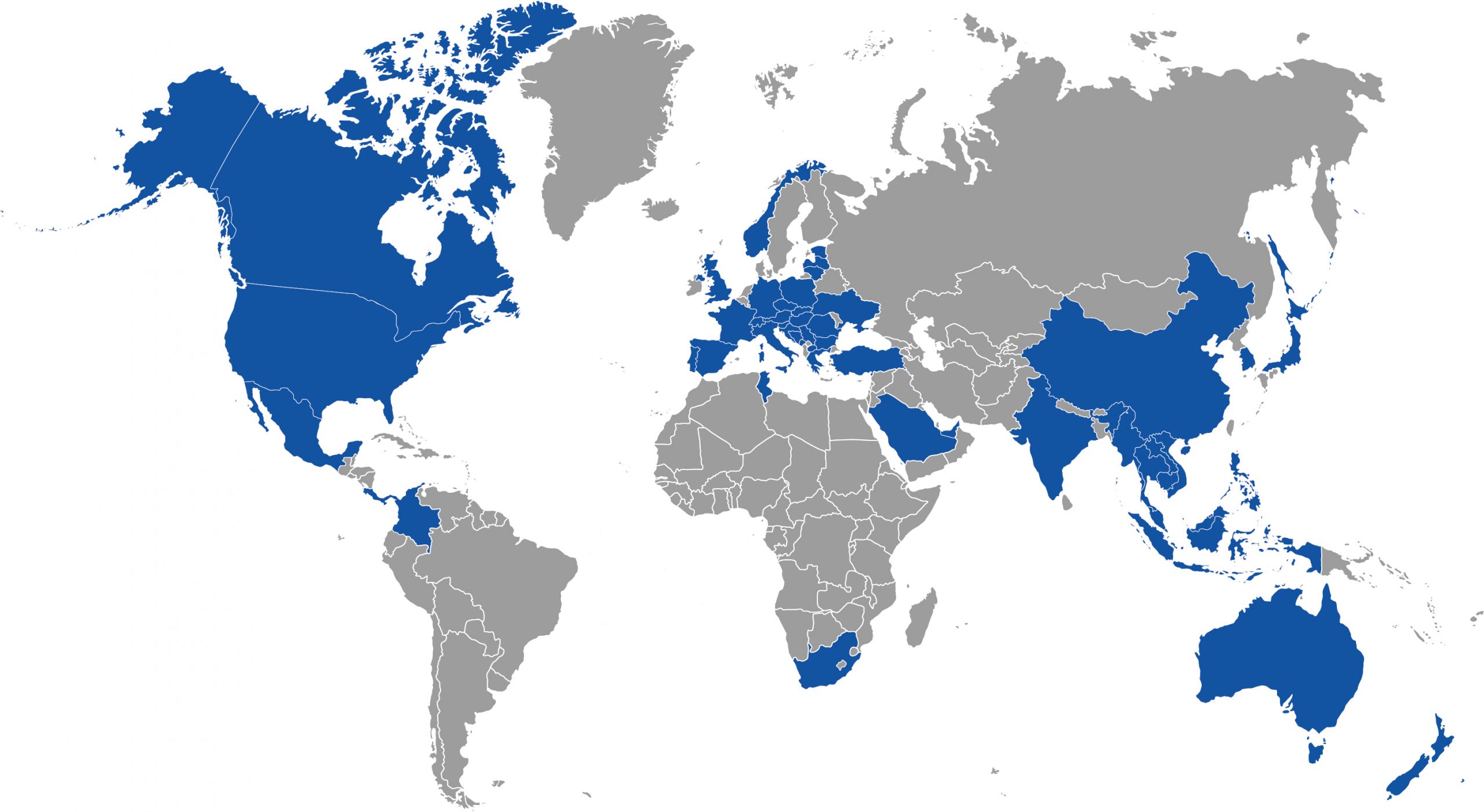

Our 3D scanners make every day work easier in factories, design offices and measuring laboratories around the world.

Our advantages