Universal 3D measurement process

Perform all measurement tasks using a common process

Improved alignment toolkit

PolyWorks 2018's alignment techniques for dimensional reference points and dimensional base targets are more versatile and complete than ever: balancing of deviations for parts with integrated iterative alignment functions with assigning target reference points to features of the constructed component.

User Experience

Improved detection features, ease of use and improved tool performance in PolyWorks 2018 provide valuable benefits from a user productivity perspective:

Main Features:

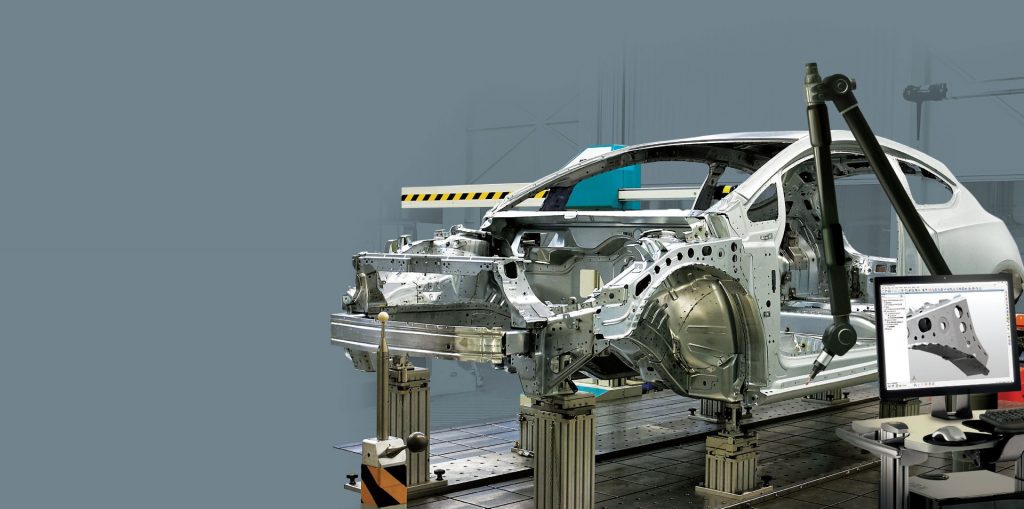

- A universal measuring platform that works with the whole range of measuring devices, such as measuring arms and manual measuring devices, devices using photogrammetry, laser tracers and manual CMM. All plugs for operating the measuring devices are available at no extra charge.

- A universal approach to all measurement tasks.

- Parametric, traceable and upgradeable solution, that automatically records the operator's intentions and ensures that changes made to measurement projects are automatically duplicated in all objects and reports in the project.

- The integrated Play Inspection function allows you to measure the next part without having to learn or write scripts.

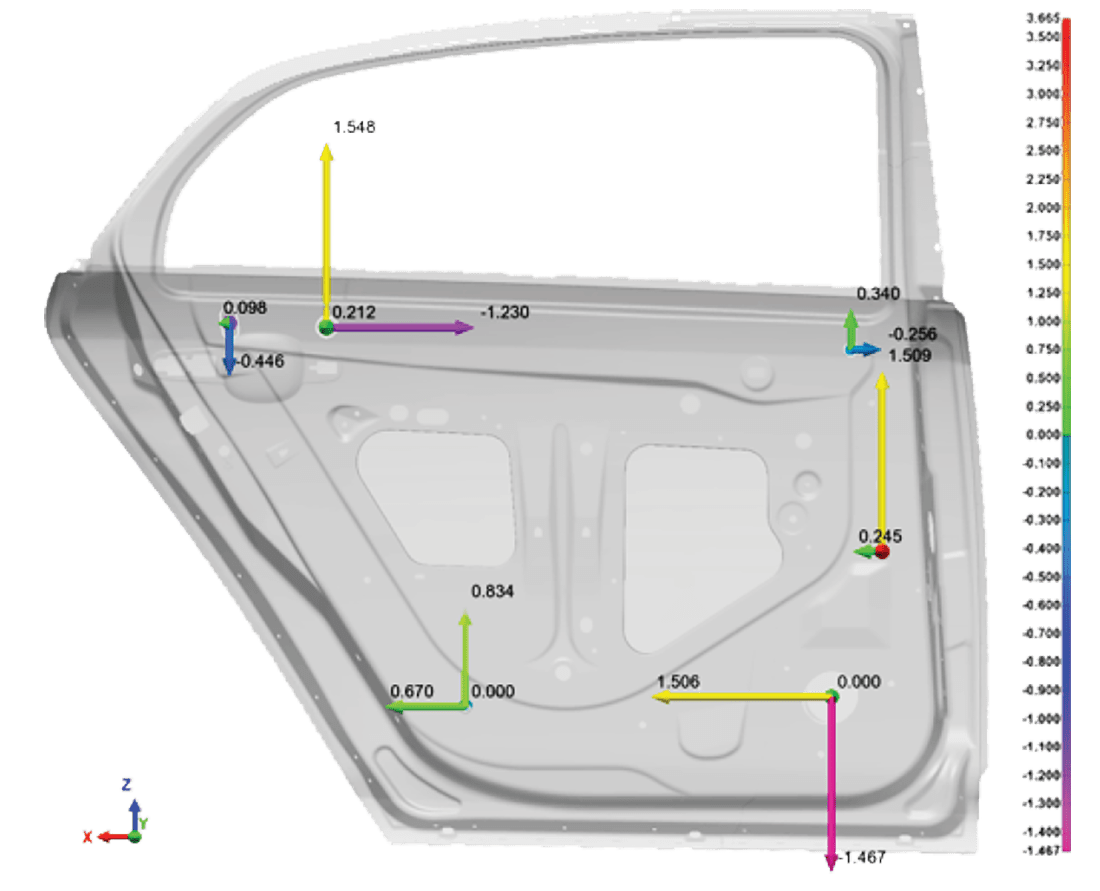

- The largest range of dimensional inspection functions on the market for complete analysis of surface, edge and section deviations, dimensioning of geometric features, flush & gap analysis, profile radii, blade dimensioning and many more.

- GD&T™ analysis ased on the algorithms described in ASME and ISO standards, advanced capabilities of dimensional base frame definition (support for base feature arrays, complex bases and partial bases), support for base modifiers and tolerance zones, radial and rectangular tolerance zones and many others.

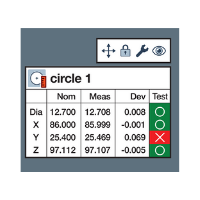

- The position control mode allows for precise positioning of parts relative to selected objects, control of deviations in X, Y, Z and 3D, visual and audible operator guidance, automatic reference object detection and much more.

- Best-in-class solution for managing multiple measuring device positions, with automatic adjustment of device positional transfer points, point analysis tools.

- A powerful set of functions to align measurement data to CAD references, including the use of measured geometric features, reference points, surface points, best fit for surface points or sections, and much more.

- Ability to work with multiple coordinate systems and multiple alignments within one project.

- Extended reporting capabilities, including configurable templates, automatic report generation and export to Adobe PDF.

- Integrated set of tools for statistical process control (SPC).

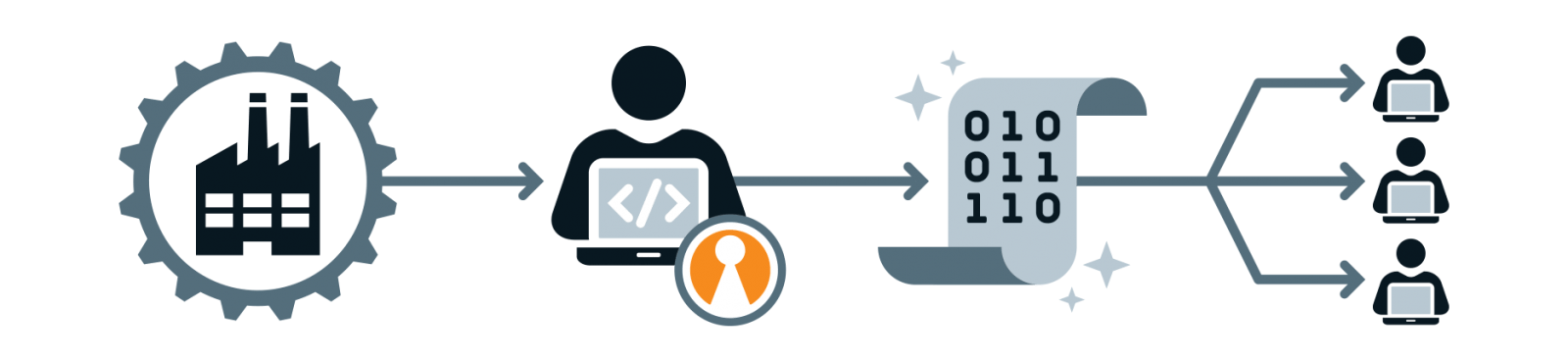

- User-friendly macro programming language for advanced process customization.

- Full compatibility with the Polyworks|Inspector™ point cloud metrology platform.

- The free Polyworks|Reviewer™ allows anyone interested to view 3D measurement results.

Implement PolyWorks | Inspector™ in any industrial environment!

Adapting PolyWorks | Inspector™ to different measurement applications in prototyping, pre-production and production environments has never been so easy!

Create and insert short macro scripts directly into measuring objects to:

Build a library of your own measuring methods tailored to each production requirement and share them with colleagues.

Check GD&T requirements

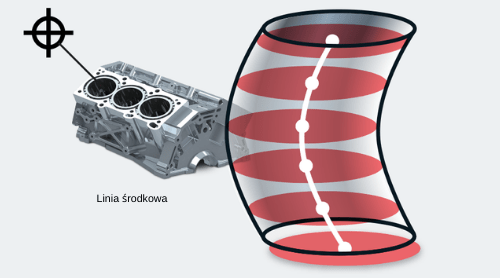

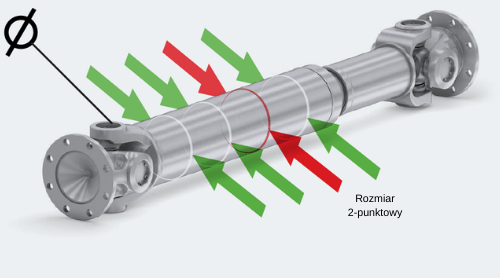

Perform more thorough inspections with the improved GD&T PolyWorks|Inspector™ toolkit, which is now compatible with the latest versions of the ISO GPS and ASME GD&T standards. Now you can use the new axle and 2-point dimension calculations together with the associated dimensional checks for quality control of components such as holes in car engines and drive shafts.

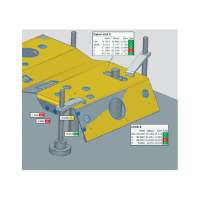

Create and edit control views easily

Intuitively create control views by displaying desired objects and their descriptions in 3D view. Use the improved control results viewer to edit and improve control views.

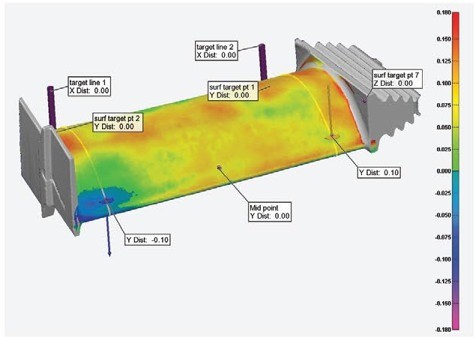

Accurately analyze feature deviations

Use the maximum and minimum deviations of the measuring points of the matched feature, as well as the direction and magnitude of the deviations of the midpoint, to analyze the measured features more effectively.