The combination of the advantages of touch and non-contact measurement with CAD software technology enables fast and accurate inspection of components. The technology of intelligent model feature detection enables defining model orientation, dimensions, tolerances, and the end result is a detailed report with colorful deviation maps.

Explore examples of applications

Explore the advantages of Geomagic Control X software

Geomagic Control X is a 3D software used for quality control tasks that enable fast and accurate inspection of parts. It is ideal for use with scanners and has the advantage of being intuitive, fast, convenient, and flexible. Learn more about the program's capabilities to help you streamline your business:

Find out more about the program

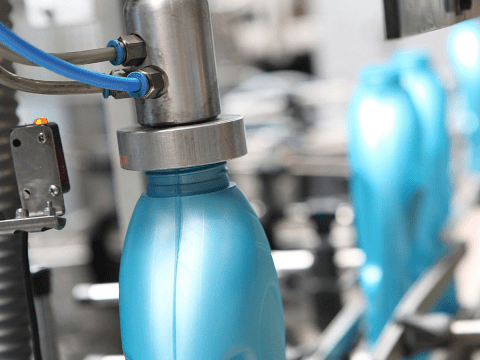

Use any 3D scanner

Control X can work with data from any 3D scanner. Direct plugins to many of the most popular systems have been developed. So you are ready for the future - you can add any 3D scanner at any time, without having to learn the new software interface.

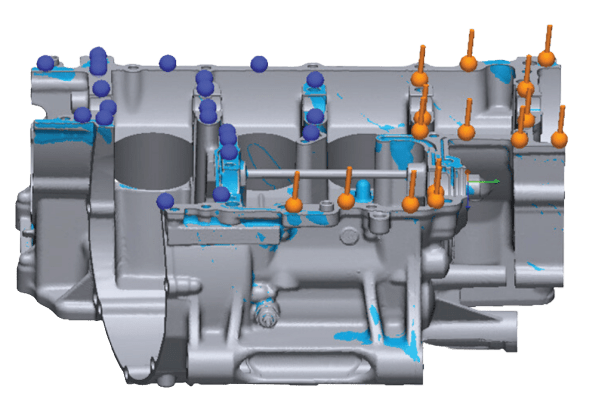

Compare scans with CAD

Beautiful, intuitive color maps show what fits in and out of tolerance and what the difference is. Control X supports countless comparison techniques, including 2D and 3D cross-sections. You get native interfaces with PMI for all major CAD systems: DS SOLIDWORKS, DS CATiA, CREO, AUTODESK INVENTOR, NX SIEMENS.

Fit as you wish

Control X has improved the fitting techniques to accommodate every control scenario: - Function-based Automatic Fit (Best Fit) - Best fit with constraint options - RPS, after features and 3-2-1 fit - Adaptive and based on.

Check for damage or surface wear

Control X can automatically estimate what is the ideal shape of the scanned object and measure the deviation to determine even small surface imperfections.

Compare scans with reference elements

You can scan the reference elements and use them for comparison as nominal models. Control X treats the scanned nominal as a CAD model because it automatically adds intelligence to each scan (for example, it knows that a plane is a plane).

Repeat and investigate to better understand

You can make changes in any part of the control process at any time. Try different alignments, different measurements, and Control X will recalculate the entire inspection process and display updated results immediately.

Immediate dimensioning

Because Control X automatically recognizes functions in the nominal models (regardless of whether they are CAD models or part of the reference elements), measuring dimensions in 2D or 3D is extremely fast and easy.

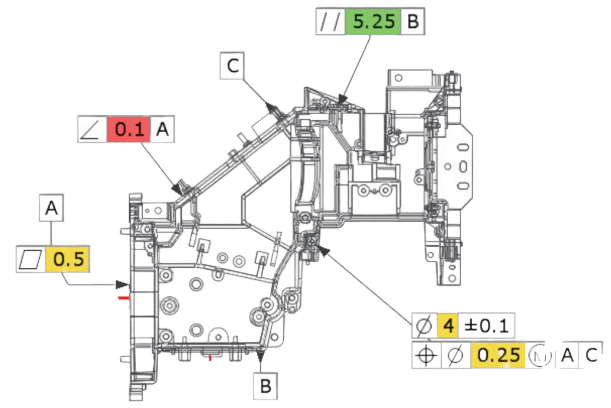

2D i 3D GD & T

Advanced geometric dimensioning and tolerance tools allow to analyze the size, form, orientation and location of objects according to ASME Y14.5M standard. Geomagic Control X measures: - Lines, angles, radii, ellipses, hole depth, hole and thickness. - Straightness, flatness, roundness, cylindricity, parallelism, perpendicularity, angularity, position, concentricity, symmetry, line profile, surface profile, catwalk and total catwalk.

Clear, interactive 3D reports for everyone

Create reports the way you want them, using templates. And don't worry if you decide to change or add something later - reports update automatically. Monitor changes over time through trend analysis. Share reports using 3D PDF so everyone can view them on their PC, Mac or phone - no special software is required.

automate the entire process

Every aspect of project control is saved in the Control X model manager. Additional parts can be checked with a few clicks with the included batch processing application, which can run simultaneously on multiple computers.

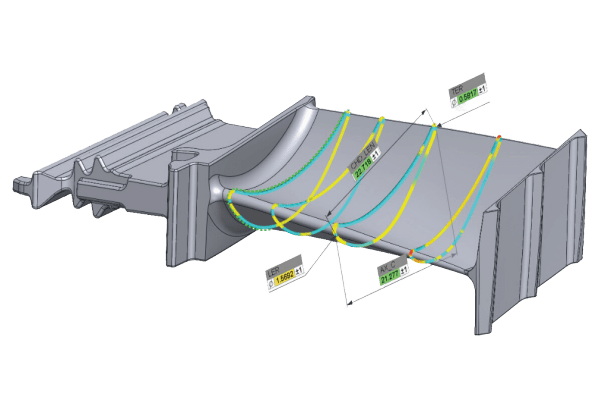

Analyse the airflakes

Control the quality of turbines or blades with the included airframe analysis tools. Control X automates the measurement of: - Airframe profiles - Position and thickness of guide and end edges - Angles and chord lengths - 2D steering analysis.