We scan products

Comprehensive 3D scanning and 3D modeling services

Our services meet the highest standards of measurement accuracy (accuracy up to 0.006 mm, certified according to VDI/VDE). We operate across the country by scanning at customer locations (our 3D scanners are mobile devices) or by performing services remotely in our testing laboratory.

As part of the services we offer scanning objects of various sizes, shapes and made of various materials.

We specialize in dimensioning elements made of materials impossible to measure by conventional methods. We perform 3D scanning services at our company's headquarters or in the location you specify. Details to be scanned should be sent by courier to the eviXscan 3D measurement department. After the service is completed, the details will be returned to you. For the 3D scanning service at your location, please contact the eviXscan 3D measurement department in advance to arrange the details.

Scanning examples for our clients

Perform a 3D scan service of the turbocharger turbine

Based on the data received in the 3D scan process, an STL model was created. Then, the STL model was created by reverse engineering to create a CAD parametric model. So you can make replacements in any technology.

What were the challenges?

complicated shape,

free surfaces,

a product which is difficult to measure by conventional methods.

Design of the CAD model of the injection mold used

Customer Cooper Standard has commissioned our engineers to make a CAD model of the injection mold. The STL model was created in the 3D scanning process. Based on this, the 3D Service engineers produced a CAD parametric model. The requisitioner performs part replacements in CNC machining technology.

What were the challenges?

complicated shape,

free surfaces of the front part,

an element that is difficult to measure by conventional methods.

Performing reverse engineering service

For our customer, the leader in plastic packaging production, we have developed a reverse engineering service. In the 3D scanning process of the supplied PET bottle, our engineers have made the CAD model. Based on this, our customer could make injection molds in mass production.

What were the challenges?

complicated shape,

sfree surfaces,

an element that is difficult to measure by conventional methods because of its flexibility.

Performance of the 3D scanning service of the rubber seal provided

For our customer, the leader in the manufacturing of automotive bodywork seals, we have performed a 3D scanning service for the supplied rubber seal. Based on the data obtained as a result of the 3D scanning process, our engineers made a CAD model that was used by our client to make the injection mold.

What were the challenges?

- complicated shape,

- free surfaces,

- an element that is difficult to measure by conventional methods because of its flexibility.

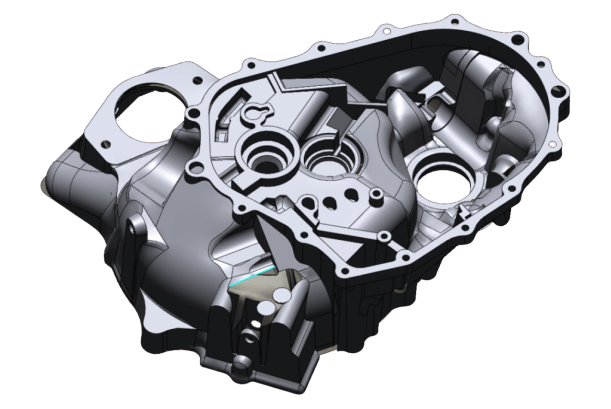

Perform 3D scan of the transmission housing

For our client from the automotive industry we have performed 3D scanning service of the gearbox housing. The 3D scan process results in an STL model that is sufficient to reproduce the element only in the 3D printing process. Our engineers based on the STL model have conducted a 3D modeling process that results in a parametric CAD model.

Order a 3D scanning service

- eviXscan 3D SA

2 Wiktora Przybyły Street

43-300 Bielsko-Biała